Automated Controls

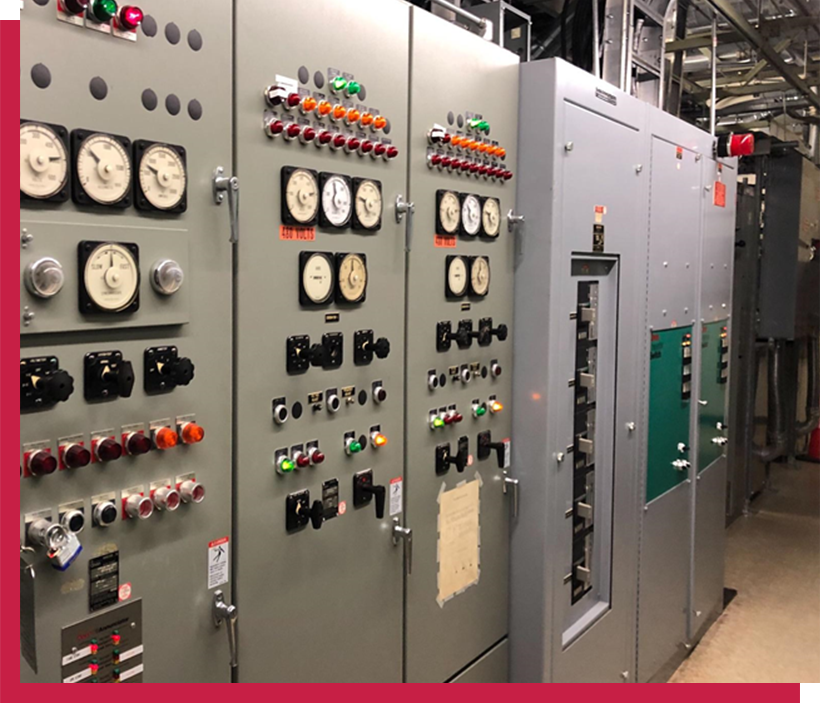

If your paralleling switchgear or emergency generator backup controls look like these photos, it’s an ancient design. It’s the same tired design from the 1960s/1970s with an updated PLC, touchscreen, and newer protection devices.

Most of the devices mounted on the front door provide the operator with information but the operator has to look at multiple lamps or meters and understand what they are indicating. At best, it takes trained personnel to understand, and at worst, it’s just confusing.

Generator engine/alternator actually operates.

Paragon Engineering provides control designs that have a definitive line of demarcation. The design utilizes the generator vendor’s products for controlling the engine, voltage, and synchronization with the utility or another generator.

The design allows the integration of any standard PLC from a vendor that understands the power distribution system. The vendor controls the opening and closing of the breakers via the information provided by the generator controller over an Ethernet connection.

This is what modern generator control systems look like. They don’t resemble something that was built in Thomas Edison or George Westinghouse’s lab.

The generators (1990) were retrofitted with CAT EMCP 4.4 controllers and the ASCO (1990) paralleling controls were retrofitted with Emerson Rx3i and touchscreens.

The benefits? The local CAT dealer has a service contract for the engines and the EMCP 4.4 rolls up into that.

The Emerson integrator control design provides a wealth of digital/analog information and operation located in one location.