Repair and Refurbishment Offers

Repair and Refurbishment Offers

Paragon Engineering also operates a repair and refurbishment shop. The work within the shop includes breaker repairs, troubleshooting, preventive maintenance, and refurbishment of older Medium Voltage and Low Voltage breakers.

In the last 2 years, Paragon Engineering has refurbished 50 Medium Voltage 5 VK – 15 KV vacuum breakers. Those breakers include General Electric Powervac, Westinghouse VCP-W, Square D VR, and Siemens GMI.

Vacuum breakers have existed since the 1970s. The technology was originally estimated to last 20 – 30 years. The last 50 years indicate the breakers with proper maintenance and replacement parts can

operate for 50 years or more. There has been no “maintenance-free” technology to replace the vacuum breaker. There have only been updates to how the close/trip mechanism operates the breaker.

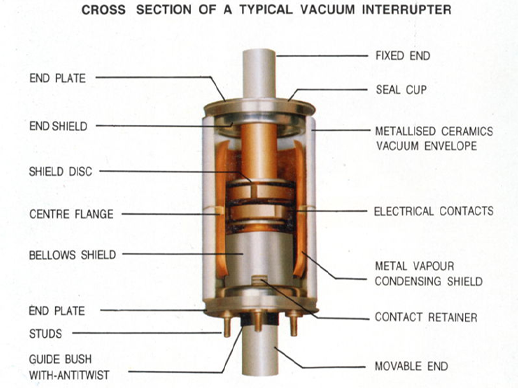

Vacuum breakers operate on the principle that the contact points opening/closing occurs within a vacuum cylinder. The vacuum cylinder minimizes the arcing created by the opening and closing and protects the operator and electrical distribution equipment. The photo on the right represents a typical vacuum interrupter.

Vacuum interrupter integrity is determined by the seal of the bellows

located at the bottom of the vacuum interrupter and around the

moving contact stem of the interrupter. Interrupter integrity or seal

is determined by hi potting the vacuum interrupter and measuring

the milliamps of current flow during the test. The test voltage is

generally 2.5 times the breaker rating and the current flow should be

less than 5 milliamps (each manufacturer specification can vary).

Magnetron Atmospheric Condition testing can also be performed

to determine the life span of the vacuum bottle.

The vacuum bottle is the heart of a vacuum breaker. As long as the

spring charging/discharging mechanism is intact, the breaker can

be refurbished for many more years of operation.