Westinghouse VCP-W Refurbishment (1990)

Westinghouse VCP-W Refurbishment (1990)

for ALL electrically charged Medium Voltage breakers are essentially the same but each manufacturer has their specific design nuances that

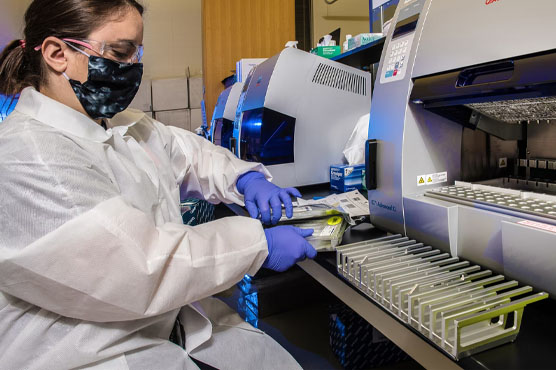

require special tools or processes for disassembly/assembly. The process begins with a breaker timing test. The test set can remotely

charge/close/trip the breaker and record the response time in milliseconds. This is a key indicator for the mechanical health of the breaker

and used as a reference when the refurbishment process is completed.

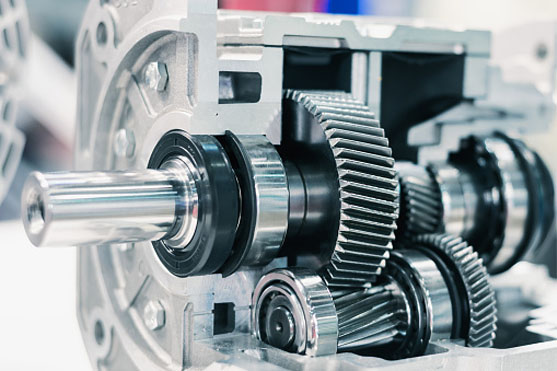

The refurbishment process also contains the typical preventive maintenance process of cleaning, inspecting, and lubrication of bearings and

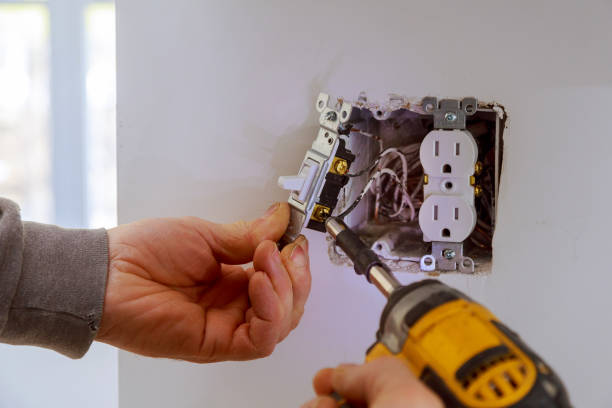

gear trains. The electrical refurbishment includes the replacement of the vacuum interrupters, charging motor, close/trip coil, anti-pump relay,

limit switch inspection/test, internal IO block inspection/test, and inspection/cleanup of internal wiring. When the process is completed, the

breaker is once again timing tested, meggered, doctored, and hi potted.

Tin plating of the bus and MAC testing is customer option. Repairs of the jack shaft and charging gear train are sent to a machine shop.The cost

of refurbishment is less than 50% of a retrofill replacement breaker. The retrofill replacement breaker will have the same anticipated 20-year

life span. The refurbishment does not require modifications to the breaker cradle, racking mechanism, or runbacks to the bus. Performance

(close & trip) times are in line with a new replacement breaker.